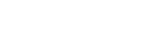

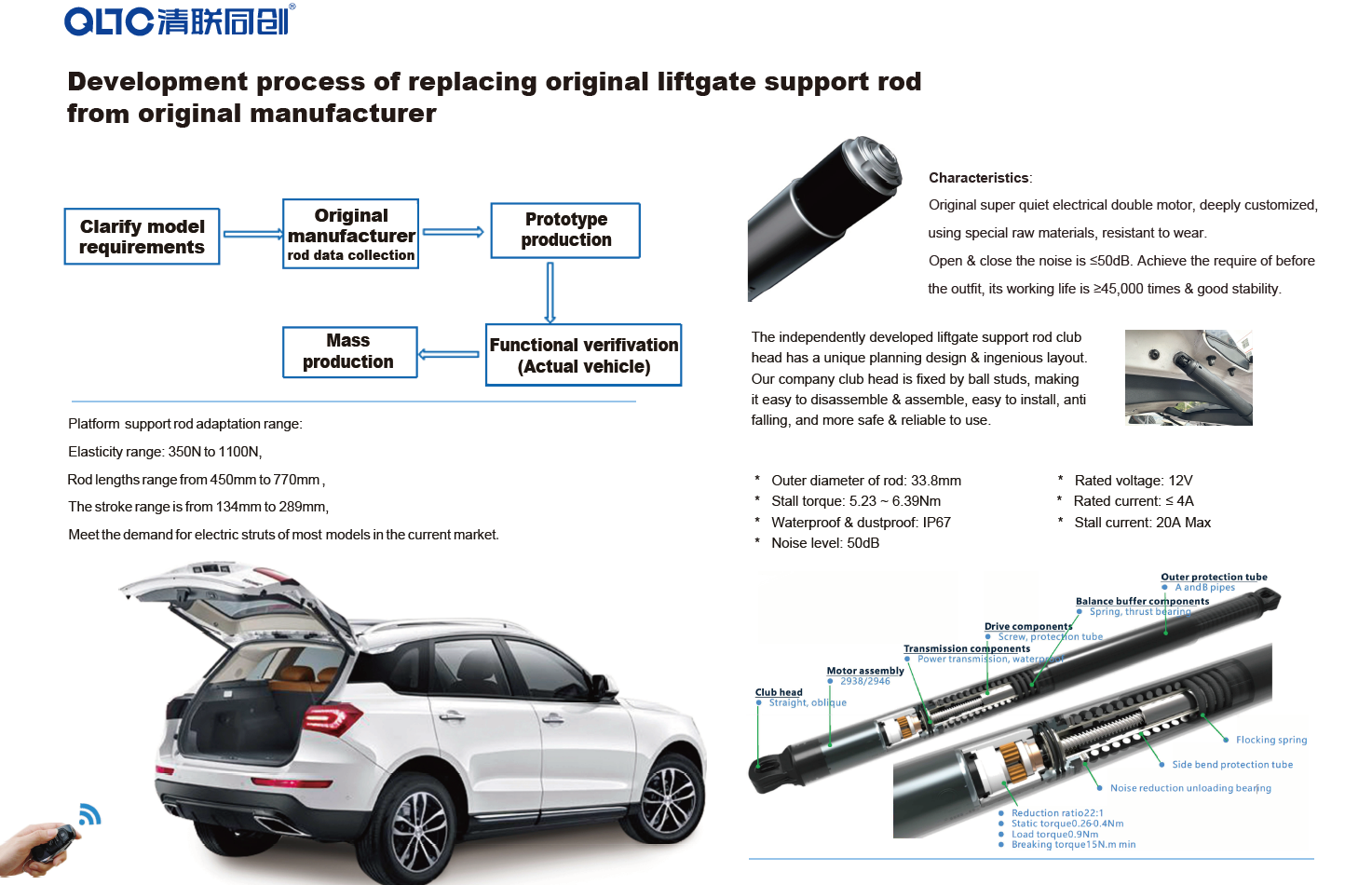

QLTC team utilizes a standardized technical review process to ensure the required technology, production quality, and marketability of project requests.

1st, Initial checks are completed for the product plan and project tasks, including preliminary analysis, material and technology requirements, and estimated costs.

2nd, Update of project plan and identified risks, along with guiding the development and simplification of the ongoing project plan.

3rd, Review the design and software of the original vehicle's 3D outline drawing base, and evaluate physical prototype, conduct testing and evaluation of the prototype with documented findings.

4th, Check the status of design development makes sure that required changes are implemented, conduct reliability testing and document results, issues are communicated and verified to proper departments, and work on necessary updates, redo testing, and verify results.

5th, And verification of applied changes on the hardware and software follow customer's requirements, along with evaluation of test results before moving to full-swing production. We take numerous product tests to ensure our company power tailgate & pedal are up to par with the highest market standards. 100+ Test Cases, 6000+ Test Runs.

6th, Retest samples at the same time with our customers, and verification of applied on the hardware and software follow customer's full requirements.

7th, A comprehensive technical review on manufacturing to meet the requirements for mass production and delivery.